When storage performance matters, turn to Suberizer!

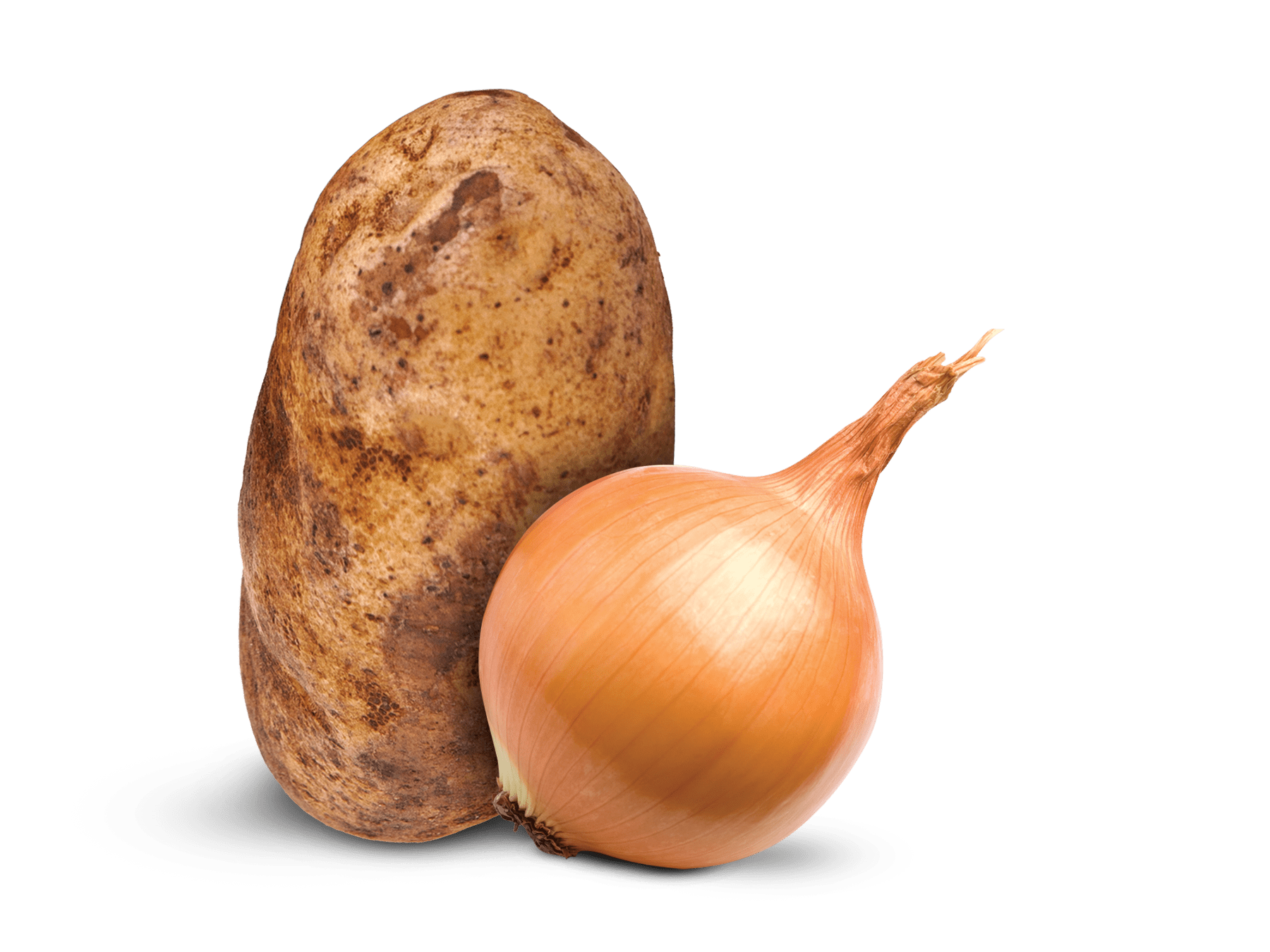

If you need a new storage solution for your raw potatoes or onions and want to maximize product quality while minimizing losses due to improper supply air, Suberizer is here to help. With more than four decades of experience in raw potato and onion storage, our products provide the best possible performance at an affordable cost. We are in this business with you.

We offer two primary raw product storage systems, which are customizable to a growers’ particular needs.

The Suberizer Envelope Storage System

Suberizer, Inc. was the first in the industry to develop the Envelope system. Envelope storage is ideal for protecting your potato harvest.

The Suberizer Curve Storage System

The Suberizer Curve Storage System utilizes a unique curved design, which helps maximize storage flexibility for your onion harvest and minimize construction costs.

We can manufacture raw potato and onion storage facilities of every size needed in the industry. We have the ability to design around a growers’ product and their unique specifications.

Learn More: About Suberizer / Storage Systems

AirEverywhere Floor:

Our unique design ensures uniform air distribution to minimize losses. Whether you’re piling or using palletized boxes AirEverywhere is the heart of a successful storage plan.

Complex Air Delivery

Our goal is to minimize static pressure drops throughout the storage facility and maximize the air delivered to the pile. In service of this goal, the AirEverywhere Floor System utilizes thousands of floor vents that deliver even, constant, uniform airflow throughout the entire pile or storage bay.

Engineering-First Approach

Suberizer’s engineering-first approach allows us to design the overall system with an emphasis on excellent fluid dynamics. The Suberizer external fanhouse is fundamental in uniform air distribution.

Custom Design Builds

Suberizer, Inc. manufactures buildings in house as well as works with several other building manufactures to design and construct any sort of building our clients’ may need to go along with their storage facility. We are with them all the way.

Learn More: Potato Storage / Onion Storage / Pre-engineered Metal Buildings

Our Approach

Minimizing loss and maximizing returns is important to our clients – and it’s important to us. That’s why we take a unique approach with our raw product storage solutions. Learn more below and see what sets Suberizer, Inc. apart from the competition.

Latest News

Suberizer is Exclusive BTU Ventilation Dealer for Washington and Oregon

In 2021, Suberizer, Inc. was proud to become Washington and Oregon’s exclusive BTU Ventilation dealer, offering industry-leading products.